Empowers Enterprises to Improve their Asset Efficiency with IoT powered Predictive Analytics

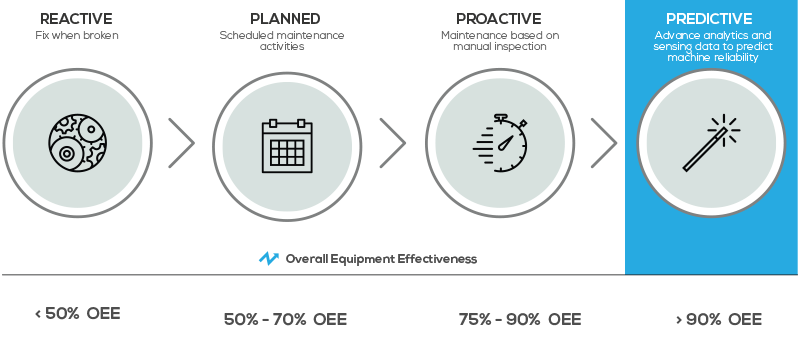

Transition from Reactive to Predictive Maintenance using SmartSense

PowerGenome

The engine that drives SmartSense

PowerGenome detects any change in the mechanical behavior of an equipment which reflects in electrical signals.

Early Fault Detection

Compared to Existing Methods.

Independent

of Brand of Equipment.

Higher Reliability

Due to Minimal Sensors.

200 Million

Data Points Analyzed Daily

4000 Equipment

Being Analyzed using PowerGenome

Acquire

MONITORS MULTIPLE ENERGY SOURCES

Plug and play integration with 200+ sensors and equipments

Seamless data integration with 3rd party System

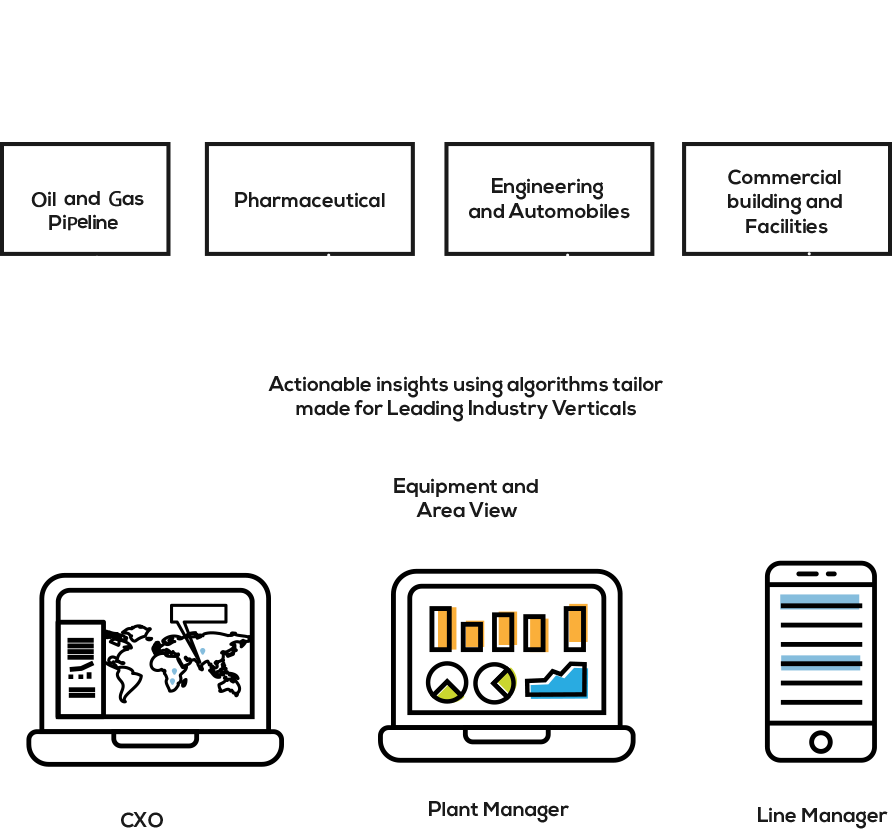

Analyze

Creation of Plant and Asset

Digital Twin using PowerGenome

Automated Fault Detection and Diagnostics (FDD) using Digital Models

- Factory & Building Layout

- Production Batches & Processes

- Production Cycle

- Working Hours

- Asset Make & Life

- Asset Rating

- Asset Running Hours

- Downtime

- Maintenance Schedules

- Product Quality

DIGITAL TWIN

Act

The SmartSense Journey

Transition from Reactive to Predictive Maintenance using SmartSense

Request A Demo